Save time and money on site!

Introducing 2415, the remedial wall bracket from MAFI. This is a great example of how MAFI helps our customers to solve the problems they face in their every-day life.

The estimated total cost for taking down, re-designing and re-building a wall mounted telecom site is approximately 10,000 Euros including:

|  |

The remedial wall bracket 2415 is a substantially lower investment from MAFI, it only requires a sky lift or one person in climbing gear to replace the existing wall mount.

It is also a much faster and safer way to upgrade a site instead of over plating the old wall mounts.

For more information please contact info@mafigroup.com.

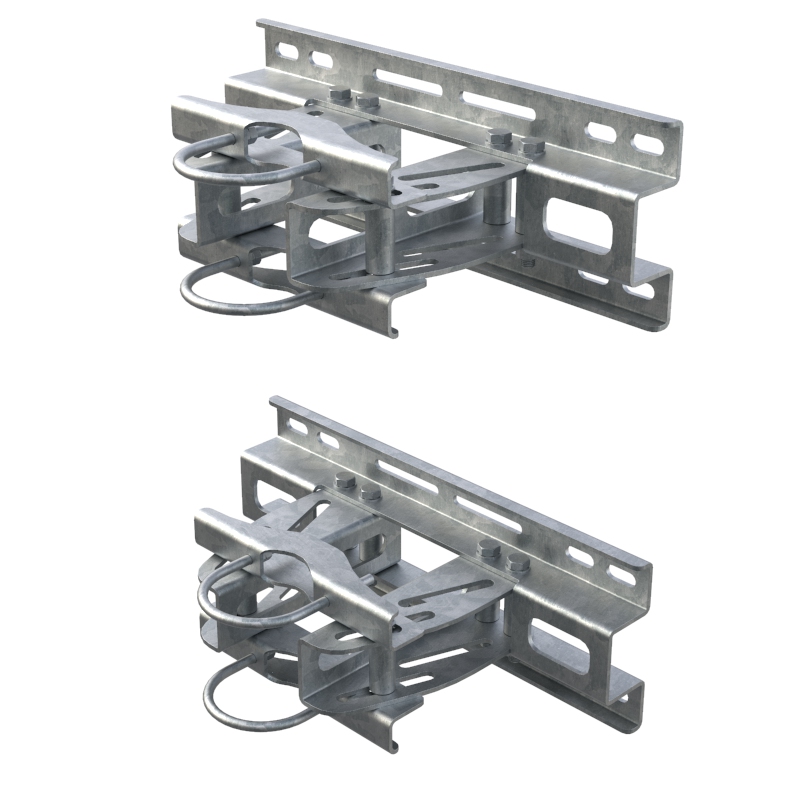

This product is a portrait-style low profile back-to-back radio mount designed to fit a wide range of radio equipment hole patterns. Upper and lower arms are independent when using the U-bolts, making it possible to mount dissimilar radios on each side. Using the bushing nuts instead makes it easy to mount identical radios.

|  |

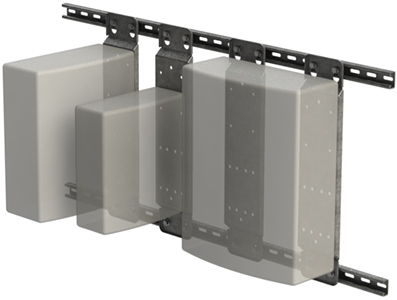

The Universal Remote Radio Bracket is developed to accomodate and combine remote radio units by several different vendors in a very economical solution. Visit www.mafigroup.com for equipment hole patterns and also functional layout for attaching to C-rail system (below). For equipment with a horizontal c/c wider than 80 mm (3.15 in) an extra bracket is needed.

|  |

The key hole pattern on the bracket makes it easy to mount. All necessary bolts and channel nuts are included in the kit.

We sat down with Tony Monda, CEO of Sealtowers to talk about the latest project Sealtowers and MAFI executed.

Can you please give us a brief background about projects that MAFI have been involved in and delivered material for?

– As of present we have completed three important projects with MAFI.

Two of these projects were focused towards adding capacity to our already existing tower sites. The other one was a new site.

Some solutions has been to your assistance?

The solutions offered have adequately addressed the needs we had especially in terms of our desired need of adding capacity.

Likewise we believe our own clients have been impressed with the installations provided from MAFI.

Can you present some example?

– We have an existing tower in Mombasa that was loaded on the top, MAFI supplied us with a novel tower extension solution that added capacity.

– Another example was adding more capacity to another existing site, the solution provided by MAFI allowed us to add capacity to the tower without affecting equipment and operations of our other clients using our tower.

– The last example MAFI delivered a rooftop solution for a new site we are building.

What was so interesting was we were able to complete installation in less than 24 hours. The solution offered compared to what other use doesn’t require us to drill or hack into the rooftop. MAFI needs to be commended for this design.

|  |  |

Why did you choose a MAFI’s solution/solutions?

MAFI was chosen out of an immediate need Sealtowers had, and also, we were looking towards getting a competent supplier for future and upcoming projects.

MAFI’s strengths in the projects? Can you please describe?

– MAFI has a more hands-on approach compared to other suppliers, when it comes to their solutions. We have noted that MAFI’s approach has been to conduct a joint site visit with Sealtowers rep, this is key and important for designing a more appropriate solution.

We have also noted that MAFI have fast knowledge and experience when it comes to telecom infrastructure. And for this they on the way to becoming a well trusted supplier in Africa. To date MAFI has been instrumental in assisting us in execution of our mentioned projects before or on time.

How do you see or estimate the expansion of the telecom infrastructure in the future in Kenya / Africa?

– Africa should be considered as the next frontier when it comes to demand for telecom infrastructure. Majority of the Telecos in Africa have on going and future plans to expand their network coverage, this translates in need for adequate infrastructure to address this need. The same is expected when rollout of 5G network begins in Africa.

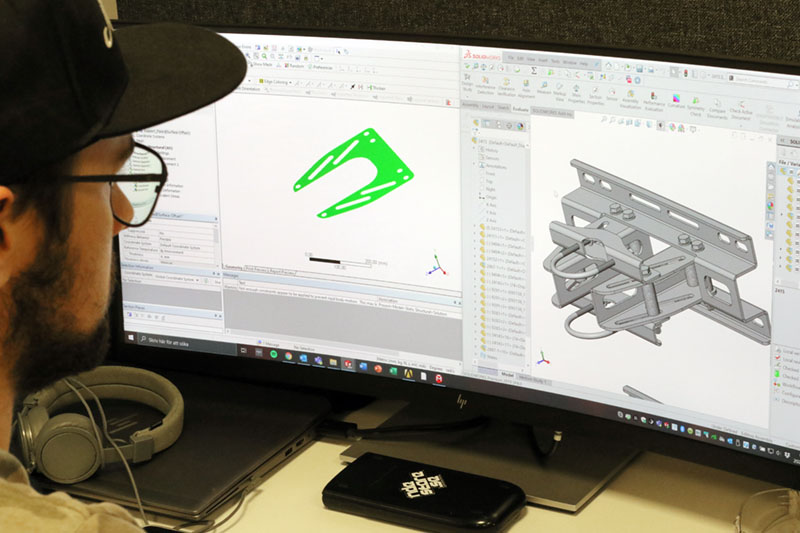

We met up with Per Tägtström, Chief Technical Officer at MAFI to talk about product development.

What is the MAFI’s R&D department’s thoughts on design?

– Our products are designed to be of safe, reliable, easy to install with a high and consistent quality meeting the customer needs. During the product development process, every component is designed and optimized using FEA(Finite Element Analysis) techniques and the properties are further verified by physical testing in our laboratory and at external testing facilities.

About your work to reduce environmental impact, what material or materials are used and what parameters are important to consider?

– Our products are made of galvanized steel, which is a fully recyclable material with a, compared to other metals, such as Aluminum, a small CO2 footprint. Furthermore, galvanized steel is formable, available as high strength material, cost effective and offers, with a careful design, a very low PIM alternative.

MAFI is certified according to EN 1090, what is a CE marking and why is that important?

– Structural constructions, such as off-set brackets or platforms are required to be CE marked within EU according to EN 1090. MAFI is certified according to that standard, which means that we meet very high demands on competence, quality and traceability of our products. A CE marked product is guaranteed to comply with the quality requirements in EN 1090 and with the Declaration of Performance (DOP) we guarantee that the product is safe to use within the specification.1

|  |

The design and the cooperation with the customer, how does the process work?

– A good design is all about meeting the customer needs. Our products are always developed in close cooperation with our customers and refined from early designs with the assistance of customer feedback on concept ideas and prototypes. MAFI have started something that we call MAFI Academy, a way to visualize our solutions “ in real life”.

Interesting, MAFI Academy; in short, please describe the benefits and opportunities.

– The MAFI Academy is an opportunity for our customers that together with us at MAFI, learn more about site and product design and to find new solutions for the needs of the market. During the Covid-19 restrictions, MAFI Academy is available as webinars, but in the future, we will run seminars on site in Mora at our excellent outdoor exhibition area.

In MAFI Academy(MA), we train our customers thru our webinars in, CE marking, FEA-analyzes, how to choose the right bracket, loads on steel structures, to name a few things. MA is not only about teaching but also about getting feedback from our users. In our combined showroom and training facility, we can together with our customers develop new products and improve existing ones.

If you want to attend a webinar please contact following:

For Americas: Raphael de La Soujeole, raphael.delasoujeole@mafigroup.com

For Europe: Nigel Topp, nigel.topp@mafigroup.com