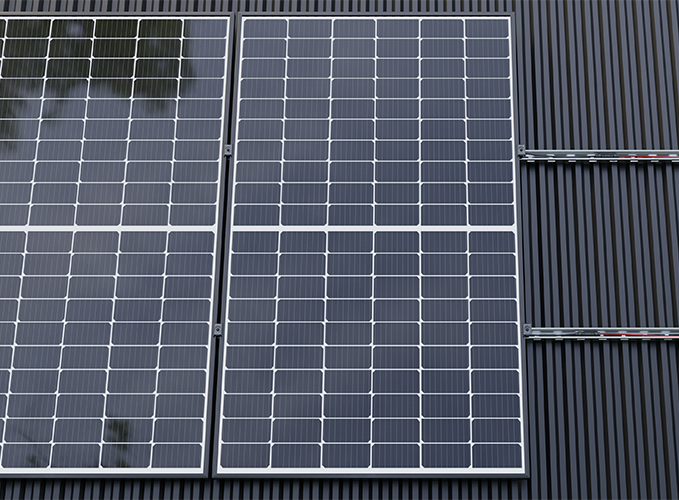

MAFI – founded in Sweden in 1992 and now with a presence in the Americas, Europe and Asia — is an international leader in the design and development of mounting solutions. Our global position comes with global responsibilities. While our core business is in the telecom industry, we have recently expanded into solar energy.

Sustainability has been a part of our vision from the start, and considering the current climate crisis and environmental concerns, we have made our ambitions more focused. Our long-term environmental commitment is aligned with the Paris Agreement of keeping the earth’s temperature rise below 1.5˚C.

MAFI has set measurable goals in order to halve its emissions for Scope 1 & 2 by 2030 and minimize its overall environmental impact. Our corporate decisions are guided by the UN Sustainable Development Goals (SDGs), doing our part to operate in a socially, economically and environmentally sustainable manner. –

Our immediate aim is an all-electric vehicle fleet and recycling programs. But perhaps where we find our most crucial sustainable advantage is right where we started – with sustainably sourced steel.

Climate change is already causing severe harm to societies and the global economy. We are taking unacceptable risks with Earth’s life support systems if global average temperatures continue to rise. The UN 1.5°C ambition means to return to pre-industrial levels as soon as possible. The urgency is real and business as usual is not an option.

Andreas Westholm, CEO Volati Communication says, “At MAFI, production and design choices are made with a great deal of thought to life cycle thinking, longevity, quality, production methods, health and economy. Complying with environmental laws, regulations, and other requirements are but a minimal requirement for us.”

At MAFI Group, it’s natural to behave ethically in all aspects of business. To set good examples in the way we act towards each other, as employees, and the way we treat our business partners, suppliers and customers. We always respect laws and regulations wherever we do business.

Beyond that, sustainability is a big part of everything we do. In essence, we work with both an internal and external perspective, where the internal covers what we can do to reduce our own impact and the external covers what we can do to reduce our value chain emissions.

Let’s begin with the value chain emissions, which represent a larger share of our emissions. Here, our target is to reach net zero by 2040. From our perspective, this affects purchased raw materials, products and services, transport and product use.

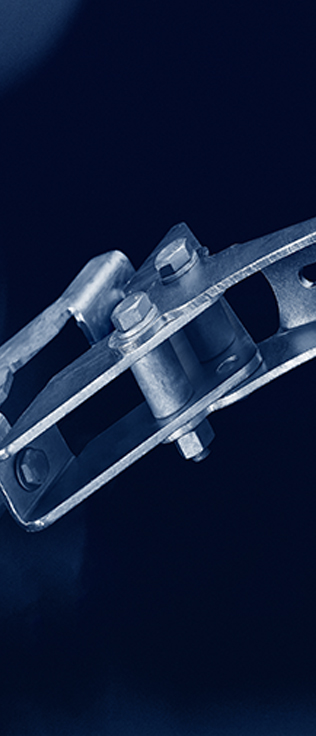

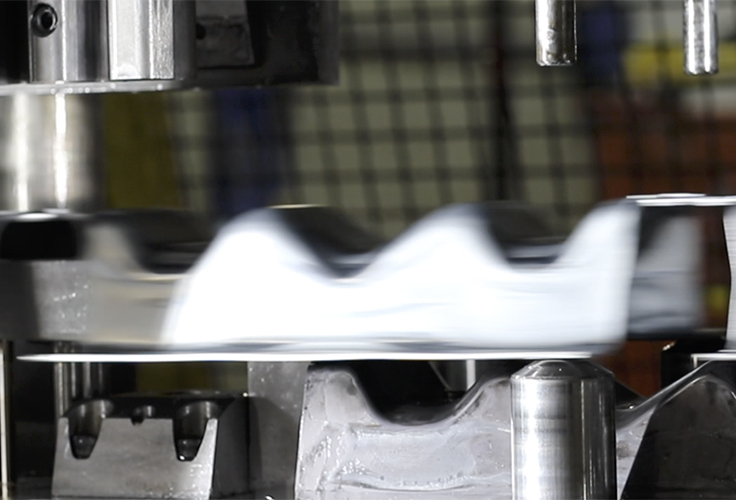

In our product development, we only use recyclable material for our main components, to strengthen our position of sustainable production. MAFI has chosen galvanized steel over other metals or raw materials since galvanized steel can be recycled any number of times, without limitation. Optional materials lose their capabilities after three to five recycling repetitions.

Per Tägtström, Chief Technical Officer at Mafi Group, says “One primary reason for working with galvanized steel is that it is fully recyclable without losing in quality and strength. If steel was not 100 percent recyclable, we would not be using it. We are also looking forward to the opportunity to start working with fossil-free steel from Sweden in a not-too-distant future.”

Steel has other advantages. Steel is less likely to warp or bend from weight, force, or heat. These resistant properties make it one of the most durable industrial materials. With zinc-based galvanizing, adding a high level of corrosion resistance, steel has an extremely long lifetime, adding to its sustainability.

In the not-too-distant future, MAFI is keeping a close eye on adding fossil-free steel to our raw material base.

We see three main ways to reach the goal: 1) Higher focus on scrap reduction already in early design stages. 2) Increase the use of high strength steel, thereby enabling thinner gauge material. 3) Continue the light solution design work already started by MAFI.

MAFI is a global company operating on local markets. Since each market has its own characteristics, MAFI has created four regions to keep us local on a global market: Europe, the Americas and Asia.

They have in common to source as much as possible of its production regionally, as long as those materials can be produced sustainably.

A present requirement is that all regions must source at least 70% of its production from within its region. The average percentage of local production for MAFI Group will grow during 2023 following upcoming production changes.

Being local on a global market, MAFI wants to reduce the environmental footprint through minimizing financially and environmentally costly transportation. Steel is inherently heavy and bulky. With carefully selected production sites in almost every MAFI region, we manage to reduce our environmental footprint, both in terms of choosing the most sustainable sources, and in terms of reducing shipping.

Still, logistics remains a factor and we are doing all that we can to choose the most sustainable alternatives. One method is to replace some shipping by sea with rail transport. Another is to evaluate our last mile deliveries with electric-based alternatives. We are also looking into facilitating drop shipments directly to our customers from regional production sites.

Now, when we look at our internal measures to reduce our own direct emissions, we have identified several areas with available improvements. Our electricity consumption is a major one. We aim for fossil free energy usage when it comes to our facilities and work environment. We have already invested in environmentally friendly heating, and we measure energy consumption in real-time.

Historically, MAFI has had a fleet of fossil fuel cars. The decision to own a fully electric company vehicle fleet was taken in 2020, using hybrid vehicles during a transition period. Today our car fleet are fully electric.

We use digital tools that help our customers optimize their solutions without the need for physical travel.

As a company, MAFI has always worked with sustainability in mind. The positive effects have always been there, but the work with measurability has unfortunately lagged. However, that work is now highly prioritized, and more and more data is being collected and compared.